Our Story

Shaalvi Organics is a culmination of Shalu Agarwal and Ravi Agarwal’s quest to create food that makes you feel better and look better.

In 1998, Ravi Agarwal (co-founder of Shaalvi Organics) discovered his “ikigai”!

The endless joy and opportunities in organic farming resulted in the formation of Shaalvi Organics. It started with purchasing a small piece of land and an indigenous cow. Over the last 22 years, the size of the farm has tripled, with hundred of cows now grazing and breeding over it.

With his sheer passion and love for this art, Ravi Agarwal, the driving force behind Shaalvi Organics, has developed expertise in cattle breeding and organic farming. Today, he is one of the most sought-after experts in the industry with awards under his name. He’s also appeared on various news media multiple times.

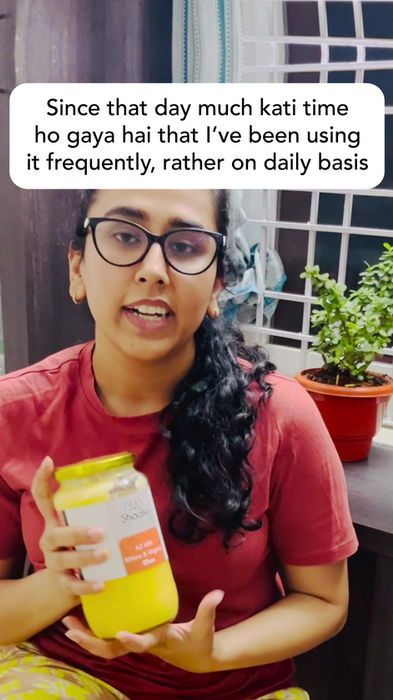

On the other hand, Shalu (co-founder of Shaalvi Organics) felt the need to create high nutritional value ghee to replace the processed ghee available in the market.

She returned to the basics and applied the traditional Vedic cooking methods to prepare the highest quality product. Shalu ensured that the final product was hygienic, safe, and of superior quality using wooden and earthen pots in every step of the ghee-making process.

Shaalvi Organics offers their vision of fresh, organic, and sattvic products from our farms to your plate.

Ghee Making Process

Bilona and Organic Ghee is made using Gir Cow’s fresh milk. The milk is slowly heated on a low flame and brought to a boil. It cools down naturally in big containers. Culture is added to it in earthen pots to turn it into curd. This curd is kept for 24 – 30 hours to be fermented. The curd is now ready to be churned.

Churning of curd is done in steel pots (food grade quality) with a wooden rai, rotating clockwise and then anticlockwise after every 4-6 rounds for 25 – 30 mins so that all maakhan is extracted eventually from the curd. When the top layer shows maakhan, we add filtered drinking water in it. This helps us to remove maakhan easily from the rest of the buttermilk. It is collected in pots and the buttermilk is given to our cows as it is rich in Vitamin B12 and Calcium and works as an immunity booster for them. We take utmost care of hygiene and cleanliness during the process of separating maakhan.

Maakhan is washed 2-3 times in cold water to remove any buttermilk that is left in it during the process. This gives a good texture to our ghee.

It is now heated on a slow flame with in-between stirring. When the maakhan turns into clear liquid with no white bubbles of buttermilk to be seen in it, the flame is turned off and ghee is allowed to cool down.

After 4-5 hours, we strain the ghee with a Mulmul cloth to remove any tiny solid particles in it and now the Ghee is ready to be utilized.